Precision 5-Axis Milling Machining, Non-Standard Parts Machining

- Delivery in as fast as 5 days

- 100%Outgoing Quality Control

- 3D CMM measurement report

- 3D Scanning Digital Analog Comparison

Vertical Machining Center

- One-setup completion for 5-sided machining,hole positional tolerance ±0.003mm,production efficiency improved by 30%

- Smooth cavity surface (Ra≤0.6μm),max cavity depth 200mm,zero chip accumulation risk

- Flatness ≤0.0015mm/m,contour repeatability ±0.002mm,stable quality for mass production

Vertical Machining Center

- One-setup completion for 5-sided machining,hole positional tolerance ±0.003mm,production efficiency improved by 30%

- Smooth cavity surface (Ra≤0.6μm),max cavity depth 200mm,zero chip accumulation risk

- Flatness ≤0.0015mm/m,contour repeatability ±0.002mm,stable quality for mass production

Vertical Machining Center

- One-setup completion for 5-sided machining,hole positional tolerance ±0.003mm,production efficiency improved by 30%

- Smooth cavity surface (Ra≤0.6μm),max cavity depth 200mm,zero chip accumulation risk

- Flatness ≤0.0015mm/m,contour repeatability ±0.002mm,stable quality for mass production

Ultra-Precise 5-Axis Machining Parts

5-axis milling is suitable for turbo blowers, turbochargers, valve bodies, blades, aviation structural parts, complex medical parts, strict X-detection internal quality inspection, small batch processing of raw materials, long-term demand and mass production provide cost Optimize plan.

Online Services

We provide online consultation, quotation inquiry, and order placement for procurement to simplify your purchasing process.

The Advantages of 5-Axis Milling Machining

The core advantages of 5-axis milling machining are one-time forming of complex structures, high precision without deviation, and dual excellence in efficiency and quality. It can break through the processing limitations of 3-axis milling and serves as a core processing solution for high-end precision parts.

Process control

We have many cases of difficult five-axis machining projects, and every step from design to production completion ensures the feasibility of the process.

- Material Performance Verification

- Overall quenching

- Internal Gravity Elimination

- Electron beam welding

- Dynamic balance G1

- 3DCMM comparison

- Complete FMEA, PFMEA

Superior Machining Capability for Complex Curved Surfaces & Irregular Structures

Significantly Enhanced Machining Efficiency

Reduced Clamping Times, Improved Machining Precision

Optimized Tool Paths: Protecting Tools and Parts

Maximum part size for 5-axis CNC milling

The more advanced of the milling machine family, 5-axis centers can produce parts with more complex geometries. These machines require fewer machine setups so they are more productive.

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for all materials | 950 x 650 x 650 mm | 37.4 x 25.59 x 25.59 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

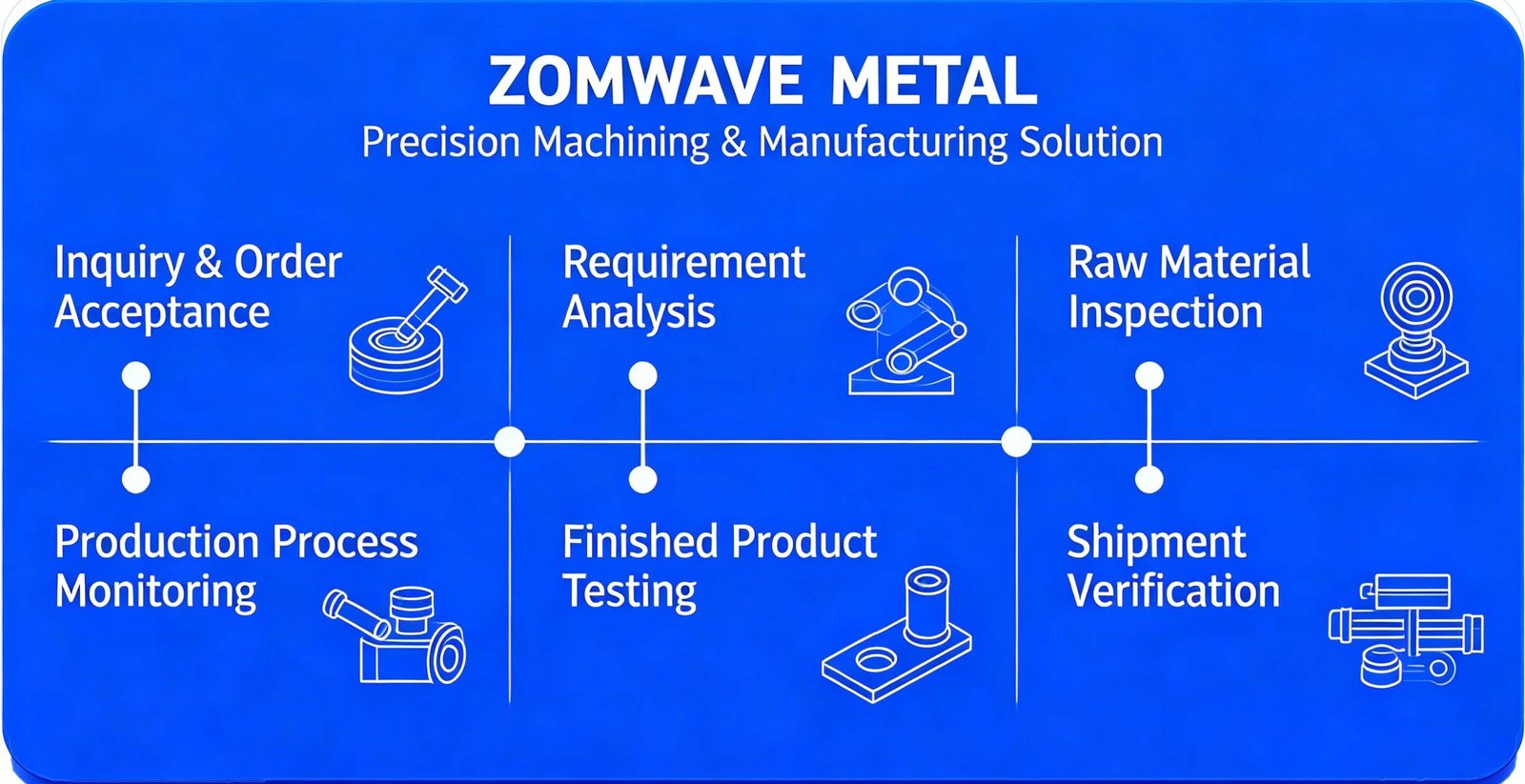

Full closed-loop quality management

For inquiries or email: sales@zomwavemetal.com

Send Us an Email

Get instant quotes

Free solutions for your products.

Supports uploading of 2D/3D image files in different formats.

Detailed product information is for engineers accurately to calculate costs.

Contact Us

Mon -Fri: 9:00 AM – 6:00 PM

Zone B, Building 4, Huiye Science and Technology Park, Guanhuang Road, Guangming District, Shenzhen City

S‐6‐3A, Setia Tri‐Suites, Persiaran Kelicap, 11900, Bayan Lepas, Penang

☎ +86 18028785424

Email: sales@zomwavemetal.com

We will respond to your needs within 24 hours of receiving your email.