Inspect. Verify. Deliver. – Zomwave Quality Control

- Measur Data System

- Six Sigma Management

- 100% Shipping Inspection

- Full Process Measurement Report

Trusted by the best companies in the world

Quality Management Policy

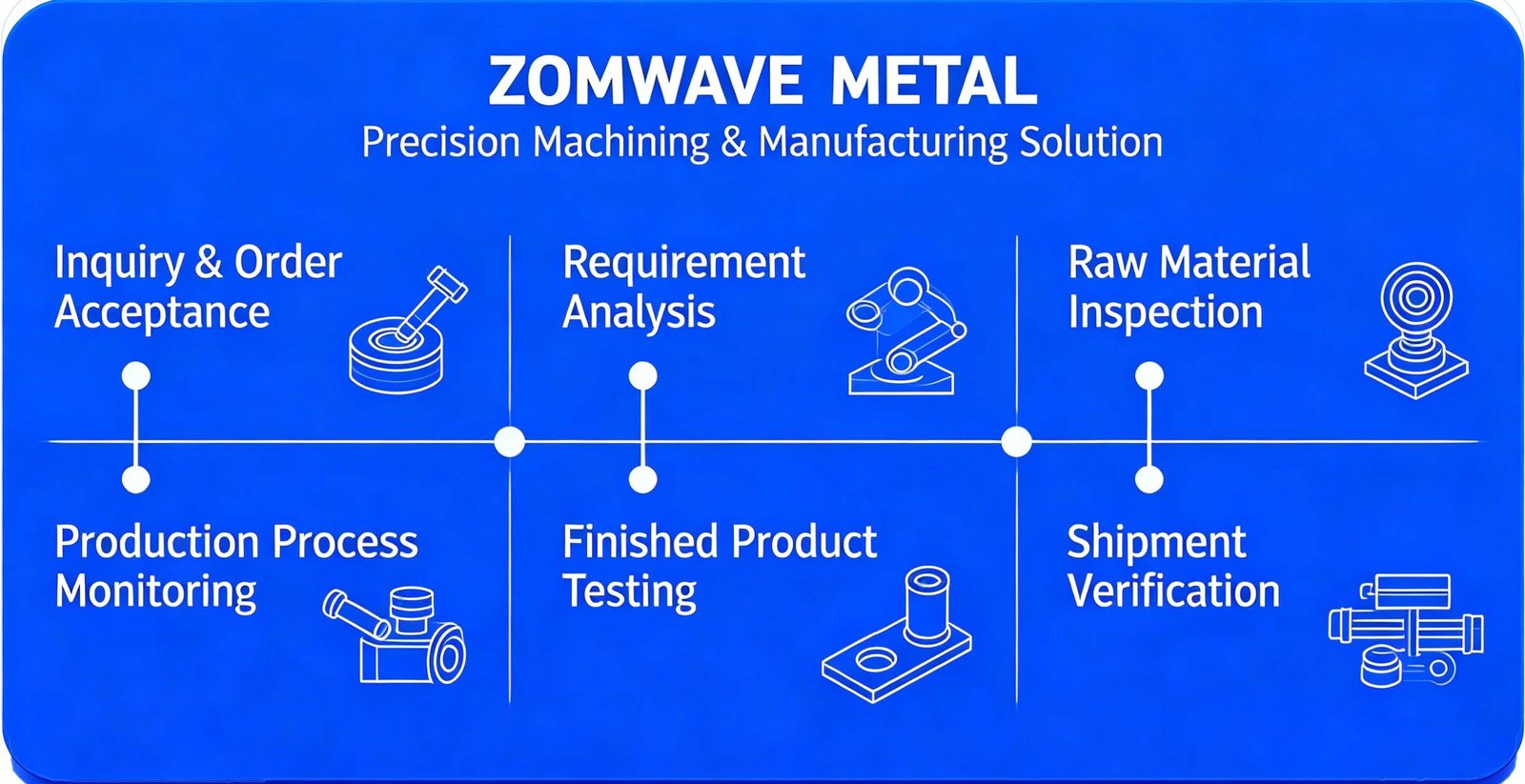

QC Policy:From Material to Shipment

Material-to-shipment full-process control: every custom part meets your strict tolerance.

ISO-Aligned QC Policy for Global Trust

ISO-compliant QC policy: the foundation of risk-free collaboration for global clients.

Non-Standard Parts: Tailored QC Policy

Non-standard parts get tailored QC: matching your complex design & tolerances.

Your Tolerance, Our QC Standard

Your tolerance is our QC standard: micron-level precision for custom components.

Full closed-loop quality management

Demand analysis

We clarify the customer's project requirements and establish inquiry forms and purchase orders. Customers can check the progress of all projects and their respective sub-modules at any time, and also view the real-time production status of purchase orders through our online platform.

Process Control

All production processes will adopt a fully closed-loop process management. If the measured data exceeds the tolerance range, the MES will lock the production equipment, automatically schedule production to avoid delayed delivery, and allow real-time online query of the production dynamics of POs

Supply Chain

It is mandatory to obtain ISO 9001 Quality Management System certification and test Zomwave-specific test samples; after review, a supply chain agreement shall be signed, with a focus on quality rules, privacy, and confidentiality clauses.

Quality & Delivery

It supports real-time online query of measurement data, enables traceability of part engraving process numbers and purchase order numbers, allows export of measurement data reports as electronic documents, and the shipping documents include material reports, CMM full-dimensional reports, surface treatment reports, certificates of conformity, and packing lists.

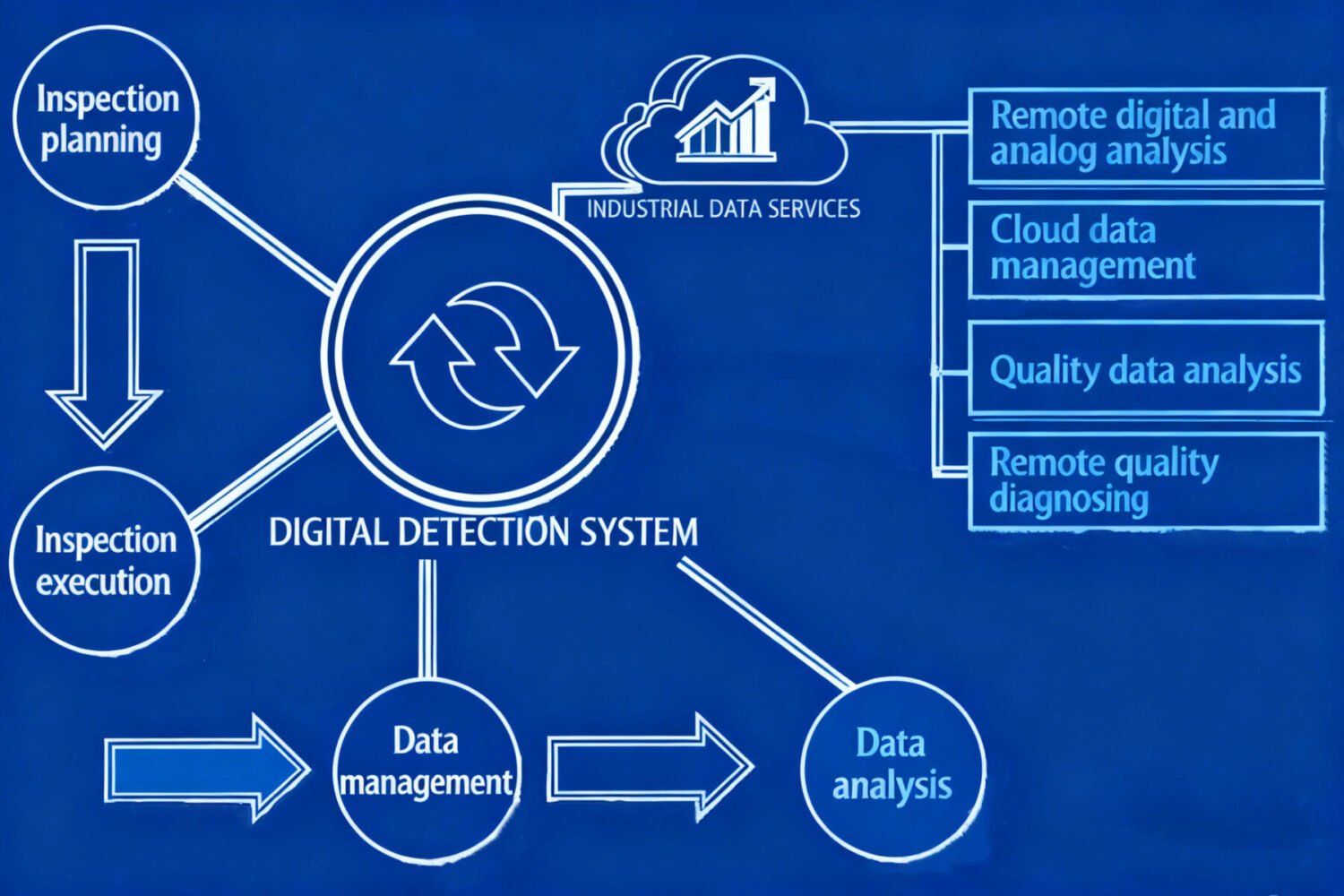

Digital Quality Management System (DQMS)

A structured quality inspection job driver and process management system based on product digital models (2D/3D) to meet the quality inspection and control of product implementation processes in the MBD environment.

Quality Control Process

Product Appearance Inspection Standard

Consistency Requirements Inspection

The Consistency Requirement Inspection Standard is a quantitative basis for ensuring that products/processes maintain a uniform quality level across batches, time periods, and scenarios.

Product Consistency: Dimensional Consistency, Surface Consistency, Performance Consistency

Process Consistency: Production Process Consistency, Inspection Method Consistency

Visual Inspection

Basic Implementation Requirements

- Environmental Conditions: Unified lighting (standard light source of 400-600 lux, no strong light reflection/shadow), observation distance of 30-50 cm, viewing angle of 45°±15°.

- Personnel Requirements: Visual acuity ≥ 1.0 (after correction), no color weakness/color blindness, and qualified through training and assessment on standard defect samples.

- Auxiliary Tools: Magnifiers (5-10x) and colorimeters (for auxiliary judgment of color deviation) may be used; reliance on subjective experience for judgment is prohibited.

Send Us an Email

Get instant quotes

Free solutions for your products.

Supports uploading of 2D/3D image files in different formats.

Detailed product information is for engineers accurately to calculate costs.

Contact Us

Mon -Fri: 9:00 AM – 6:00 PM

Zone B, Building 4, Huiye Science and Technology Park, Guanhuang Road, Guangming District, Shenzhen City

S‐6‐3A, Setia Tri‐Suites, Persiaran Kelicap, 11900, Bayan Lepas, Penang

☎ +86 18028785424

Email: sales@zomwavemetal.com

We will respond to your needs within 24 hours of receiving your email.