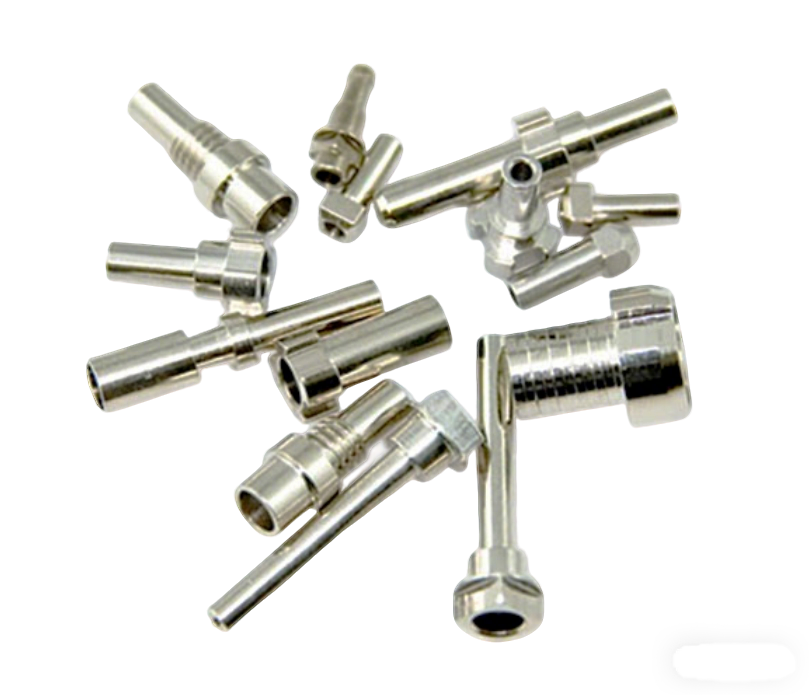

Professional CNC Turning of Various Customized Spare Parts

- Fastest Delivery Within 5 Days

- 100% Outgoing Quality Control

- 3D Measurement Report

- 3D Scan Comparison with Digital Models

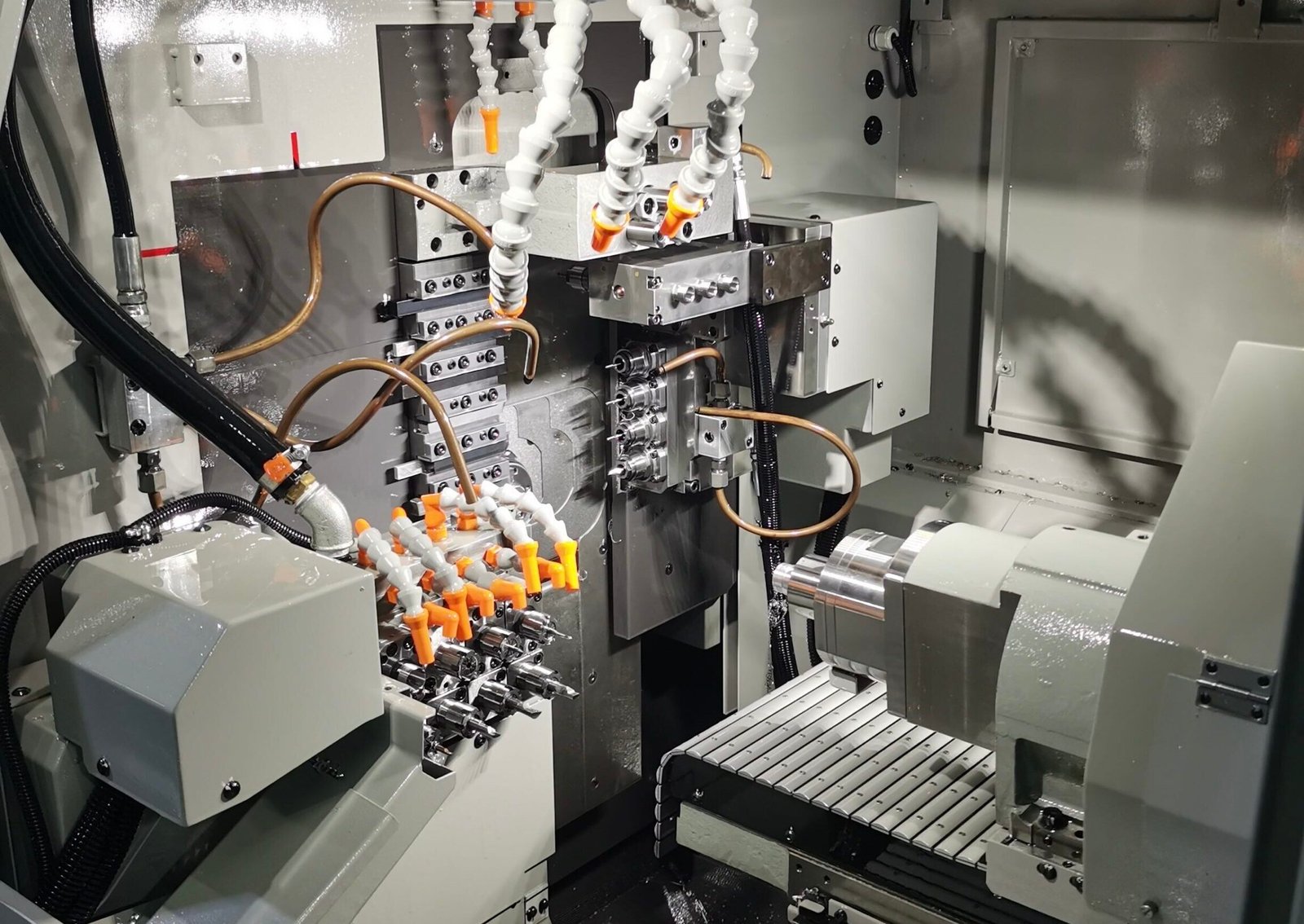

Our CNC Machining Equipment

Swiss-Type Lathe

- Max Diameter: 13mm

- Max Speed: 15,000 RPM

- Tolerance: ±0.005mm

- Medical

- Aerospace

- Automotive

- Electronics and Communications

- Robotics Manufacturing

- Energy Equipment

Swiss-Type Lathe

- Max Diameter: 25mm

- Max Speed: 12,000 RPM

- Tolerance: ±0.005mm

- Medical

- Aerospace

- Automotive

- Electronics and Communications

- Robotics Manufacturing

- Energy Equipment

Swiss-Type Lathe

- Max Diameter: 25mm

- Max Speed: 12,000 RPM

- Tolerance: +0.005mm

Applicable to parts production across the following industrial sectors:

- Medical

- Aerospace

- Automotive

- Electronics and Communications

- Robotics Manufacturing

- Energy Equipment

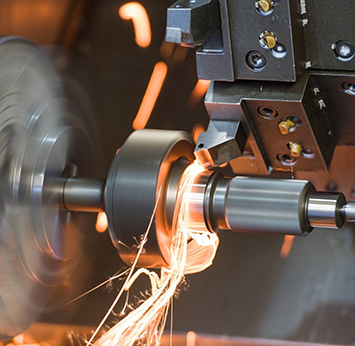

CNC Turning

Zomwave adhere to strict production processes in CNC turning and are capable of manufacturing a variety of non-standard customized turned parts.

Online Services

We provide online consultation, quotation inquiry, and order placement for procurement to simplify your purchasing process.

Maximum part size

for CNC turning

| Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 825 mm | 32.48 in |

| Maximum part length | 1500 mm | 59 in |

| Maximum swing over the carriage | 430 mm | 16.93 in |

| Maximum spindle through-hole | 65 mm | 2.56 in |

The maximum speed is 6000RPM, the maximum load-bearing capacity is 2T, and the minimum compensation parameter is 0.0001mm.

Zomwave's CNC Turning Tolerances

We adhere to the ISO 2768 standard for CNC machining.

| Limits for nominal size | Plastics (ISO 2768- f) | Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.05mm | ±0.05mm |

| Over 3mm to 6mm | ±0.05mm | ±0.05mm |

| Over 6mm to 30mm | ±0.1mm | ±0.1mm |

| Over 30mm 至 120mm | ±0.15mm | ±0.15mm |

| Over 120mm 至 400mm | ±0.2mm | ±0.2mm |

| Over 400mm 至 1000mm | ±0.3mm | ±0.3mm |

| Over 1000mm 至 2000mm | ±0.5mm | ±0.5mm |

| Over 2000mm 至 4000mm | ±1mm |

*Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing.

CNC Turning design guidelines

Check the recommended and technically feasible values for the most common features encountered in CNC machined parts.

| Feature | Recommended size | Feasible size |

|---|---|---|

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter: standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |

We have strict requirements for the turning process.

PO consistent

We ensure that every part after machining is as specified in the PO as customer requirements.

Quality check

Prior to MP shipment to ensure that each part meets order specifications and Zomwave standards.

Require consistent

Ensure conformance of parts and any required documentation prior to dispatching the order.

Send Us an Email

Get instant quotes

Free solutions for your products.

Supports uploading of 2D/3D image files in different formats.

Detailed product information is for engineers accurately to calculate costs.

Contact Us

Mon -Fri: 9:00 AM – 6:00 PM

Zone B, Building 4, Huiye Science and Technology Park, Guanhuang Road, Guangming District, Shenzhen City

S‐6‐3A, Setia Tri‐Suites, Persiaran Kelicap, 11900, Bayan Lepas, Penang

☎ +86 18028785424

Email: sales@zomwavemetal.com

We will respond to your needs within 24 hours of receiving your email.