Blog

Complete Guide to CNC Copper Machining: Properties, Alloys, Tips & Applications

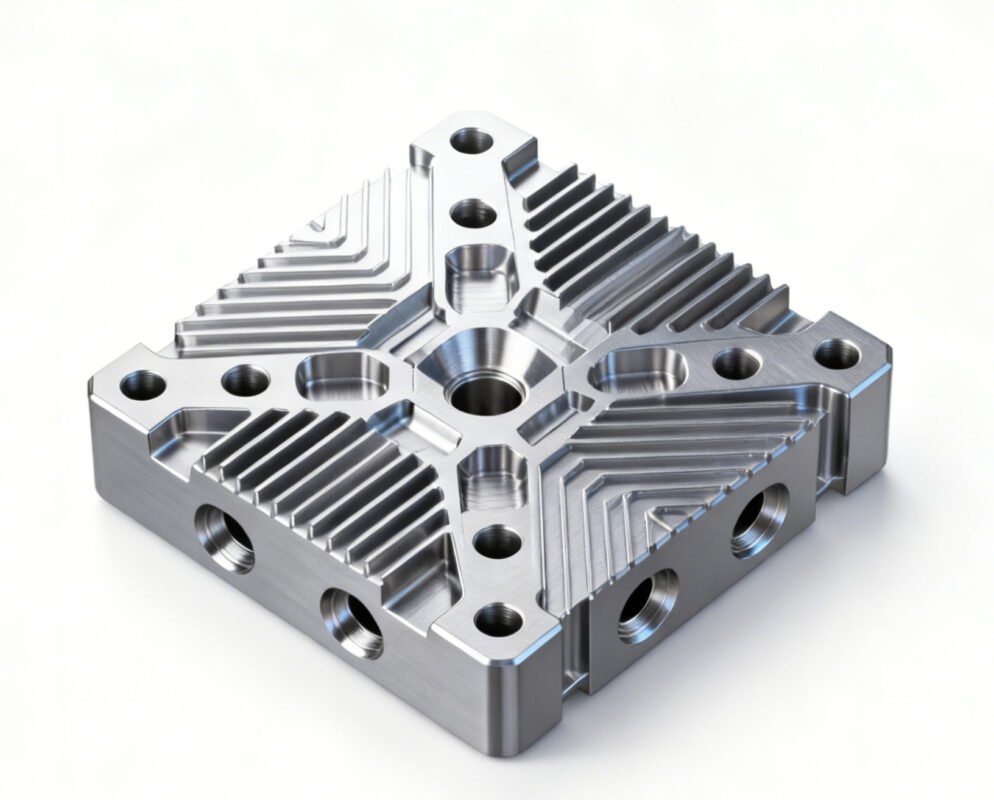

Copper, a time-honored industrial metal with exceptional natural properties, has long been a cornerstone in precision manufacturing. Renowned for its superior electrical conductivity, thermal conductivity, and excellent machinability, copper and its alloys are indispensable materials in high-end industries such as electronics, aerospace, medical devices, and automotive engineering. With the advancement of CNC machining technology, the precision and efficiency of copper part production have been significantly elevated, making CNC copper machining a critical process for manufacturing high-performance components.

In this comprehensive guide, we will delve into everything you need to know about CNC copper machining—from the fundamental properties of copper and common alloy grades to machining advantages, key process considerations, and real-world applications. Whether you’re an engineer selecting materials, a purchaser sourcing precision parts, or a manufacturer optimizing processes, this article will provide valuable insights to support your decision-making.

Key Properties of Copper: Why It’s Ideal for CNC Machining

Copper’s unique combination of physical and mechanical properties makes it particularly well-suited for CNC machining. Understanding these characteristics is essential for optimizing machining processes and ensuring part quality:

- Exceptional Machinability: Pure copper and most copper alloys have low hardness and good ductility, allowing for smooth cutting, drilling, and milling during CNC processing. This reduces tool wear and improves machining efficiency compared to harder metals like steel or titanium.

- Superior Electrical & Thermal Conductivity: Copper ranks second only to silver in electrical conductivity and has excellent thermal conductivity. These properties make CNC-machined copper parts ideal for applications requiring heat dissipation or electrical transmission.

- Excellent Corrosion Resistance: Copper forms a protective oxide layer when exposed to air, preventing further oxidation and corrosion. This makes copper parts suitable for use in harsh environments, including marine and industrial settings.

- Good Ductility & Malleability: Copper can be easily formed into complex shapes via CNC machining without cracking or breaking, enabling the production of intricate components with tight tolerances.

- Recyclability: Copper is 100% recyclable with no loss of quality, aligning with sustainable manufacturing trends and reducing material waste costs in CNC subtractive processes.

Common Copper Alloys for CNC Machining

While pure copper (C11000) has excellent conductivity, it is often alloyed with other elements (e.g., zinc, tin, nickel, aluminum) to enhance strength, hardness, or corrosion resistance for specific applications. Below are the most widely used copper alloys in CNC machining, along with their key characteristics and use cases:

1. Pure Copper (C11000, Oxygen-Free Copper)

Also known as electrolytic tough pitch copper, C11000 is 99.99% pure copper. It boasts the highest electrical and thermal conductivity among all copper alloys but has relatively low strength. Oxygen-free copper (C10200) is a variant with minimal oxygen content, offering better ductility and weldability, making it suitable for high-vacuum or high-temperature applications.

CNC Machining Notes: Easy to machine but may cause tool built-up edge (BUE) due to its ductility. Typical Applications: Electrical connectors, bus bars, heat sinks, vacuum tubes, and medical equipment components requiring high conductivity.

2. Brass (C26000, C36000)

Brass is an alloy of copper and zinc, the most common copper alloys in CNC machining due to their excellent machinability and cost-effectiveness.

- C26000 (Cartridge Brass): Contains 70% copper and 30% zinc. It has good ductility and is suitable for both machining and forming processes.

- C36000 (Free-Cutting Brass): Added with lead (3-4%) to improve machinability, making it the "workhorse" of copper alloys for CNC turning and milling. It produces small, easily evacuable chips, reducing machining time and tool wear.

CNC Machining Notes: C36000 is the easiest copper alloy to machine; low cutting forces and high speeds are achievable. Typical Applications: Fasteners, valves, fittings, gears, electrical components, and automotive parts (e.g., fuel injectors).

3. Bronze (C51000, C65500)

Bronze is primarily an alloy of copper and tin, though modern bronzes may include aluminum, silicon, or nickel. It offers superior strength, wear resistance, and corrosion resistance compared to brass.

- C51000 (Phosphor Bronze): Contains tin and phosphorus, providing excellent fatigue resistance and electrical conductivity. Ideal for high-precision, high-wear components.

- C65500 (Aluminum Bronze): Copper-aluminum alloy with exceptional strength and corrosion resistance, even in marine and high-temperature environments.

CNC Machining Notes: Harder than brass; requires sharper tools and optimized cutting parameters to avoid tool wear. Typical Applications: Bearings, gears, marine hardware, aerospace components, and medical instruments (e.g., surgical tools).

4. Cupronickel (C70600, C71500)

Cupronickel (Cu-Ni) alloys combine copper with nickel, offering outstanding corrosion resistance in saltwater and high-temperature environments. They also have good mechanical strength and ductility.

CNC Machining Notes: Moderate machinability; requires cutting tools with high wear resistance (e.g., carbide). Typical Applications: Marine propellers, heat exchangers, offshore oil and gas components, and electrical contacts in harsh environments.

Advantages of CNC Machining for Copper Parts

CNC machining unlocks the full potential of copper’s properties, offering distinct advantages over traditional machining methods for producing high-precision copper components:

1. High Precision & Dimensional Consistency

CNC machining uses computer-controlled systems to achieve tight tolerances (down to ±0.001mm) and consistent part quality across batches. This is critical for copper parts used in electronics and aerospace, where even minor dimensional deviations can affect performance.

2. Efficient Processing of Complex Shapes

Multi-axis CNC machines (3-axis, 4-axis, 5-axis) can machine intricate copper components—such as complex cavities, thin-walled structures, and precision threads—in a single setup. This reduces lead times, eliminates repositioning errors, and improves production efficiency.

3. Minimized Material Waste

Advanced CNC software optimizes tool paths to minimize material waste, a significant benefit for copper (a relatively high-cost material). Additionally, copper machining chips are fully recyclable, further reducing environmental impact and material costs.

4. Versatility Across Copper Alloys

CNC machining can be easily adapted to process all copper alloys—from soft pure copper to hard aluminum bronze—by adjusting cutting tools, speeds, and feeds. This versatility makes it a one-stop solution for diverse copper part requirements.

5. Superior Surface Finish

CNC machining enables smooth surface finishes (Ra ≤ 0.025μm for precision turning) on copper parts, eliminating the need for additional polishing processes in many applications. This is particularly important for electrical components and medical devices where surface quality affects conductivity or biocompatibility.

Key Considerations for CNC Copper Machining

While copper is highly machinable, certain challenges (e.g., built-up edge, heat generation) must be addressed to ensure optimal results. Below are critical tips for successful CNC copper machining:

1. Choose the Right Cutting Tools

- Tool Material: Use carbide or polycrystalline diamond (PCD) tools for copper machining. Carbide tools offer good wear resistance, while PCD tools are ideal for high-speed machining of soft copper alloys (e.g., C11000) to avoid BUE.

- Tool Geometry: Select tools with sharp cutting edges, positive rake angles, and large chip breakers. This reduces cutting forces, prevents chip adhesion, and improves chip evacuation.

2. Optimize Cutting Parameters

Cutting parameters (speed, feed rate, depth of cut) vary by copper alloy. Below are general guidelines:

Copper Alloy | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

Pure Copper (C11000) | 200-400 | 0.05-0.20 | 1-3 |

Free-Cutting Brass (C36000) | 300-600 | 0.10-0.30 | 2-5 |

Phosphor Bronze (C51000) | 150-300 | 0.05-0.15 | 1-3 |

Aluminum Bronze (C65500) | 100-250 | 0.03-0.12 | 1-2 |

3. Use Effective Coolant & Lubrication

Coolant is essential for copper machining to: (1) Reduce heat generation (which can cause part deformation); (2) Prevent BUE by flushing away chips; (3) Extend tool life. Choose a high-quality cutting fluid with good lubricity and cooling properties—emulsions or synthetic coolants are recommended for most copper alloys.

4. Ensure Proper Fixturing & Rigidity

Soft copper alloys (e.g., pure copper) are prone to deformation during machining. Use rigid fixturing (e.g., high-precision collets, vacuum chucks) to secure the workpiece and minimize vibration. For thin-walled or slender copper parts, use support tools (e.g., live centers) to prevent deflection.

5. Prioritize Chip Evacuation

Copper chips are ductile and can easily clog the cutting zone, leading to BUE, tool damage, or poor surface finish. Ensure adequate chip evacuation by: (1) Using tools with large chip breakers; (2) Optimizing coolant flow to direct chips away from the cutting area; (3) Reducing feed rate if chip buildup occurs.

Top Applications of CNC-Machined Copper Parts

Thanks to their unique properties, CNC-machined copper parts are widely used in diverse high-end industries. Below are key application areas:

1. Electronics & Electrical Engineering

Copper’s excellent electrical conductivity makes it ideal for electrical components such as connectors, bus bars, circuit board heat sinks, transformers, and motor windings. CNC machining ensures these parts meet tight dimensional tolerances for reliable electrical performance.

2. Aerospace & Defense

In the aerospace industry, copper parts are used in hydraulic systems (valves, fittings), heat exchangers, and electrical wiring. Cupronickel and bronze alloys are preferred for their corrosion resistance and strength, while CNC machining ensures compliance with strict aerospace standards (e.g., AS9100).

3. Medical Devices

Copper’s biocompatibility, corrosion resistance, and sterilizability make it suitable for medical instruments such as surgical tools, endoscopes, and diagnostic equipment components. CNC machining produces high-precision copper parts that meet ISO 13485 medical standards.

4. Automotive Industry

CNC-machined copper parts are used in automotive electrical systems (battery connectors, alternators), fuel systems (injectors, valves), and cooling systems (heat exchangers). Brass and bronze alloys are commonly used for their durability and cost-effectiveness.

5. Marine Engineering

Cupronickel and aluminum bronze copper alloys are ideal for marine applications due to their exceptional saltwater corrosion resistance. CNC-machined parts include propellers, ship hull fittings, heat exchangers, and offshore oil platform components.

Choose the Right CNC Copper Machining Partner

While copper is highly machinable, achieving consistent precision and quality for high-end applications requires expertise in material selection, tooling, and process optimization. Partnering with a professional CNC machining service provider ensures your copper parts meet design requirements and industry standards.

At Zomwave, we specialize in CNC copper machining, with extensive experience processing all common copper alloys for electronics, aerospace, medical, and automotive clients. Our state-of-the-art multi-axis CNC machines, strict quality control system (ISO 9001/AS9100/ISO 13485 certified), and team of skilled engineers ensure precise, efficient, and cost-effective production of copper parts.

Upload your copper part’s 2D/3D drawings today, and our engineers will provide a free process evaluation, optimized machining solution, and accurate quotation within 24 hours. Let’s bring your precision copper component ideas to life!

Related Posts

Complete Guide to CNC Titanium Alloy Machining: Properties, Grades, Challenges & Solutions

Titanium and its alloys, renowned for their unique combination of exceptional properties, have become indispensable materials in h...

Complete Guide to CNC Stainless Steel Machining: Properties, Grades, Tips & Applications

Stainless steel, a versatile and durable alloy renowned for its corrosion resistance and mechanical strength, has become an indisp...

Everything About CNC Aluminum Machining & Aluminum Machined Parts

Aluminum is a relatively new industrial metal with a commercial production history of over 100 years. It is soft, durable, lightwe...

Complete Guide to CNC Plastic Machining: Materials, Tips, Applications & Advantages

Plastics have become indispensable materials in modern manufacturing, valued for their lightweight properties, cost-effectiveness,...