Blog

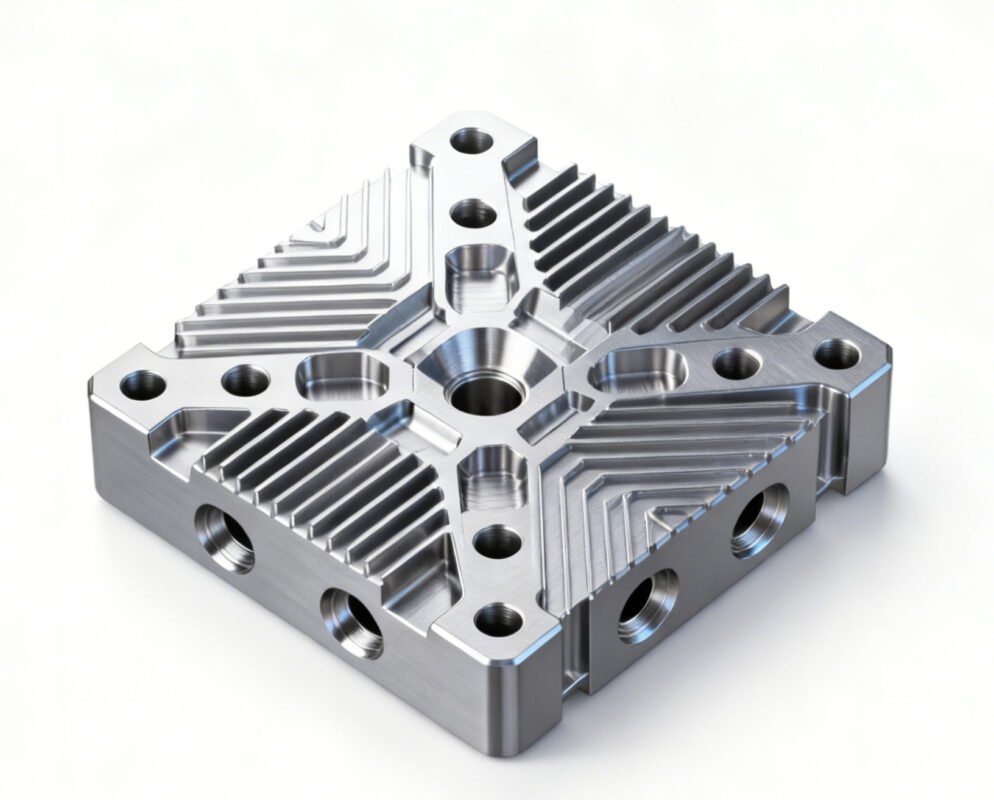

Complete Guide to CNC Stainless Steel Machining: Properties, Grades, Tips & Applications

Stainless steel, a versatile and durable alloy renowned for its corrosion resistance and mechanical strength, has become an indispensable material in precision manufacturing. From household kitchenware to high-end aerospace components, stainless steel’s unique combination of properties makes it a top choice for diverse industrial applications. With the evolution of CNC machining technology, the production of stainless steel parts has achieved higher precision, efficiency, and consistency, solidifying CNC stainless steel machining as a core process in modern manufacturing.

In this comprehensive guide, we will explore all key aspects of CNC stainless steel machining—from the fundamental properties of stainless steel and common grades to machining advantages, critical process considerations, and real-world applications. Whether you’re an engineer selecting materials, a purchaser sourcing reliable parts, or a manufacturer optimizing production processes, this article will provide actionable insights to support your decision-making.

Key Properties of Stainless Steel: Why It’s a Preferred Choice for CNC Machining

Stainless steel’s widespread adoption in CNC machining stems from its exceptional physical and mechanical properties, which align perfectly with the demands of precision manufacturing. Understanding these characteristics is crucial for optimizing machining processes and ensuring part performance:

- Superior Corrosion Resistance: The defining feature of stainless steel is its chromium content (at least 10.5%), which forms a passive oxide layer on the surface when exposed to air. This layer prevents further oxidation (rusting) and protects the material from corrosive media, making it ideal for use in harsh environments such as marine, chemical, and food processing industries.

- Excellent Mechanical Strength & Ductility: Stainless steel balances high strength with good ductility, enabling it to withstand high stress loads without cracking or deformation. This makes it suitable for manufacturing load-bearing components and structural parts that require both durability and formability.

- Good Machinability (Varies by Grade): While some stainless steel grades are more challenging to machine than others, most common grades can be efficiently processed with CNC technology when using appropriate tools and parameters. This versatility allows for the production of complex parts with tight tolerances.

- Hygienic & Easy to Sanitize: Stainless steel has a smooth, non-porous surface that resists bacterial growth, making it a staple in medical, pharmaceutical, and food and beverage industries where hygiene is paramount.

- Durability & Longevity: Stainless steel parts maintain their properties even in extreme temperature fluctuations (from low cryogenic temperatures to high heat), ensuring long service life and reducing maintenance costs for end products.

Common Stainless Steel Grades for CNC Machining

Stainless steel is classified into several categories based on its microstructure (austenitic, ferritic, martensitic, duplex), each with distinct properties and machining characteristics. Below are the most widely used grades in CNC machining, along with their key features and applications, referenced from industry material standards:

1. Austenitic Stainless Steel (300 Series)

Austenitic stainless steel is the most common category, characterized by its non-magnetic properties, excellent corrosion resistance, and good ductility. It cannot be hardened by heat treatment but can be strengthened by cold working.

- 304 Stainless Steel (18/8 Stainless Steel): The most widely used stainless steel grade, containing 18% chromium and 8% nickel. It offers excellent mechanical properties, good machinability, and resistance to most atmospheric and mild corrosive environments.

- 316 Stainless Steel (Marine-Grade Stainless Steel): An upgrade from 304, with the addition of molybdenum (2-3%). This enhances its corrosion resistance, especially in saltwater, acidic, and chemical environments. It is also tough and easy to weld.

- 303 Stainless Steel: Modified with sulfur to improve machinability, making it one of the easiest austenitic stainless steels to process. However, the sulfur content slightly reduces its corrosion resistance compared to 304 and 316. It cannot be cold-formed, heat-treated, or welded.

CNC Machining Notes: 303 requires sharp tools and optimized cutting parameters to leverage its machinability; 304 and 316 need proper coolant to prevent heat buildup and tool wear. Typical Applications: 304 – kitchenware, industrial tanks, automotive parts, architectural components; 316 – marine fittings, offshore equipment, chemical processing tanks, medical devices; 303 – nuts, bolts, gears, shafts.

2. Duplex Stainless Steel (2205)

2205 duplex stainless steel combines austenitic and ferritic microstructures, offering twice the strength of standard austenitic grades (e.g., 304, 316) and excellent corrosion resistance. It is highly resistant to stress corrosion cracking and suitable for harsh industrial environments.

CNC Machining Notes: Harder than austenitic grades; requires tools with high wear resistance (e.g., carbide) and lower cutting speeds to avoid excessive heat generation. Typical Applications: Oil and gas equipment, offshore platforms, chemical processing pipelines, desalination plants.

3. Precipitation-Hardening Stainless Steel (17-4 PH, SAE 630)

17-4 PH stainless steel offers mechanical properties comparable to 304 but with the advantage of being heat-treatable to achieve high strength. It has excellent chemical resistance and is suitable for high-performance applications requiring both strength and corrosion resistance.

CNC Machining Notes: Machinable in the annealed state; post-machining heat treatment is required to achieve full strength. Use sharp tools and adequate coolant to maintain surface finish. Typical Applications: Turbine blades, aerospace components, high-pressure valves, medical instruments.

Advantages of CNC Machining for Stainless Steel Parts

CNC machining is uniquely suited to unlock the full potential of stainless steel, offering distinct benefits over traditional machining methods for producing high-quality parts:

1. High Precision & Dimensional Consistency

CNC machining uses computer-controlled systems to achieve tight tolerances (down to ±0.001mm) and consistent part quality across batches. This is critical for stainless steel parts used in aerospace, medical, and automotive industries, where even minor dimensional deviations can compromise performance or safety.

2. Efficient Processing of Complex Shapes

Multi-axis CNC machines (3-axis, 4-axis, 5-axis) can machine intricate stainless steel components—such as complex cavities, precision threads, and thin-walled structures—in a single setup. This reduces lead times, eliminates repositioning errors, and improves production efficiency, even for challenging stainless steel grades.

3. Versatility Across Stainless Steel Grades

CNC machining can be easily adapted to process all types of stainless steel—from machinable 303 to hard 2205 duplex steel—by adjusting cutting tools, speeds, and feeds. This versatility makes it a one-stop solution for diverse stainless steel part requirements, from simple fasteners to complex aerospace components.

4. Superior Surface Finish

CNC machining enables smooth surface finishes (Ra ≤ 0.05μm for precision turning) on stainless steel parts, eliminating the need for additional polishing processes in many applications. This is particularly important for medical devices and food processing equipment, where surface quality directly impacts hygiene and performance.

5. Cost-Effective for Both Small & Large Batches

Advanced CNC software optimizes tool paths to minimize material waste, reducing costs for stainless steel (a relatively high-cost material). For small batches, CNC machining avoids the high setup costs of molding or casting; for large batches, it maintains consistent quality and efficiency, lowering unit part costs.

Key Considerations for CNC Stainless Steel Machining

While stainless steel is highly versatile, it presents unique challenges (e.g., heat generation, work hardening) that must be addressed to ensure optimal machining results. Below are critical tips for successful CNC stainless steel machining:

1. Choose the Right Cutting Tools

- Tool Material: Use carbide tools for most stainless steel grades, as they offer superior wear resistance and heat resistance compared to high-speed steel (HSS). For hard grades like 2205 duplex steel, consider polycrystalline cubic boron nitride (PCBN) tools for high-speed machining.

- Tool Geometry: Select tools with sharp cutting edges, positive rake angles, and large chip breakers. This reduces cutting forces, minimizes work hardening (a common issue with stainless steel), and improves chip evacuation.

2. Optimize Cutting Parameters

Cutting parameters (speed, feed rate, depth of cut) vary by stainless steel grade, as harder grades require lower speeds and higher feeds to avoid heat buildup. Below are general guidelines:

Stainless Steel Grade | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

303 Stainless Steel | 150-300 | 0.10-0.25 | 2-4 |

304 Stainless Steel | 100-250 | 0.08-0.20 | 1-3 |

316 Stainless Steel | 80-200 | 0.06-0.18 | 1-3 |

2205 Duplex Stainless Steel | 60-150 | 0.05-0.15 | 1-2 |

3. Use High-Quality Coolant & Lubrication

Coolant is critical for stainless steel machining to: (1) Reduce heat generation (which causes work hardening and part deformation); (2) Lubricate the cutting zone to minimize tool wear; (3) Flush away chips to prevent clogging. Use a high-pressure coolant system with synthetic or semi-synthetic cutting fluids that offer good lubricity and thermal stability.

4. Minimize Work Hardening

Stainless steel tends to work harden when subjected to excessive cutting forces or heat. To avoid this: (1) Use sharp tools to reduce friction; (2) Maintain consistent cutting speeds and feeds (avoid stopping mid-cut); (3) Use light to moderate depths of cut with multiple passes instead of heavy single passes.

5. Ensure Proper Fixturing & Rigidity

Use rigid fixturing (e.g., high-precision collets, hydraulic chucks) to secure the workpiece and minimize vibration during machining. For thin-walled or slender stainless steel parts, use support tools (e.g., live centers, steady rests) to prevent deflection and maintain dimensional accuracy.

Top Applications of CNC-Machined Stainless Steel Parts

Thanks to its unique combination of corrosion resistance, strength, and hygiene, CNC-machined stainless steel parts are widely used in diverse high-end industries. Below are key application areas:

1. Food & Beverage Industry

Stainless steel’s hygienic, corrosion-resistant, and easy-to-sanitize properties make it ideal for food processing equipment such as valves, pumps, conveyors, and storage tanks. CNC machining ensures these parts meet strict food safety standards (e.g., FDA compliance).

2. Aerospace & Defense

In the aerospace industry, stainless steel parts are used in hydraulic systems, fuel lines, turbine components, and structural parts. Grades like 316 and 17-4 PH are preferred for their high strength and corrosion resistance, while CNC machining ensures compliance with AS9100 aerospace standards.

3. Medical Devices

Stainless steel is used in surgical tools, implantable devices (e.g., orthopedic screws), and diagnostic equipment. Its biocompatibility, corrosion resistance, and sterilizability make it suitable for medical applications, and CNC machining produces parts with the tight tolerances required for patient safety (ISO 13485 certified).

4. Marine Engineering

Marine-grade stainless steel (316, 2205) is used in ship hull fittings, propellers, heat exchangers, and offshore oil and gas components. Its exceptional saltwater corrosion resistance ensures long service life in harsh marine environments.

5. Automotive Industry

CNC-machined stainless steel parts are used in automotive exhaust systems, fuel injectors, brake components, and decorative trim. Stainless steel’s durability and corrosion resistance make it suitable for undercarriage components exposed to road salt and environmental elements.

6. Architectural & Construction

Stainless steel is used in architectural components such as handrails, facades, and structural supports. Its aesthetic appeal, corrosion resistance, and durability make it suitable for both indoor and outdoor applications, even in coastal or industrial areas.

Choose the Right CNC Stainless Steel Machining Partner

While stainless steel is a versatile material, achieving consistent precision and quality for high-end applications requires expertise in material selection, tooling, and process optimization. Partnering with a professional CNC machining service provider ensures your stainless steel parts meet design requirements and industry standards.

At SANS, we specialize in CNC stainless steel machining, with extensive experience processing all common stainless steel grades for food, aerospace, medical, and automotive clients. Our state-of-the-art multi-axis CNC machines, strict quality control system (ISO 9001/AS9100/ISO 13485 certified), and team of skilled engineers ensure precise, efficient, and cost-effective production of stainless steel parts.

Upload your stainless steel part’s 2D/3D drawings today, and our engineers will provide a free process evaluation, optimized machining solution, and accurate quotation within 24 hours. Let’s bring your precision stainless steel component ideas to life!

Related Posts

Complete Guide to CNC Titanium Alloy Machining: Properties, Grades, Challenges & Solutions

Titanium and its alloys, renowned for their unique combination of exceptional properties, have become indispensable materials in h...

Complete Guide to CNC Copper Machining: Properties, Alloys, Tips & Applications

Copper, a time-honored industrial metal with exceptional natural properties, has long been a cornerstone in precision manufacturin...

Everything About CNC Aluminum Machining & Aluminum Machined Parts

Aluminum is a relatively new industrial metal with a commercial production history of over 100 years. It is soft, durable, lightwe...

Complete Guide to CNC Plastic Machining: Materials, Tips, Applications & Advantages

Plastics have become indispensable materials in modern manufacturing, valued for their lightweight properties, cost-effectiveness,...