Blog

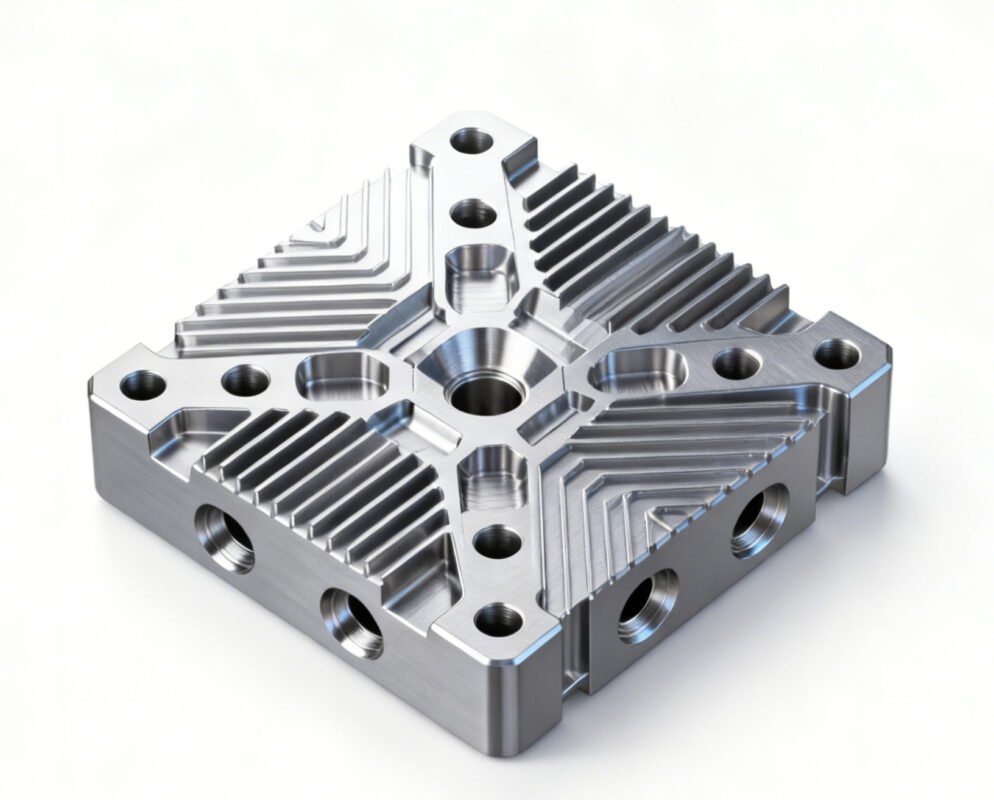

Complete Guide to CNC Titanium Alloy Machining: Properties, Grades, Challenges & Solutions

Titanium and its alloys, renowned for their unique combination of exceptional properties, have become indispensable materials in high-end industries such as aerospace and biomedicine. Offering superior rust resistance, chemical corrosion resistance, recyclability, lightweight characteristics, and high strength, titanium alloys solve numerous engineering challenges that other metals cannot address. Compared to other materials, titanium components boast longer service life and better performance. However, machining titanium alloys is notoriously difficult, requiring specialized knowledge, tools, and processes to ensure success.

In this comprehensive guide, we will delve into all critical aspects of CNC titanium alloy machining—from its fundamental properties and alloy classifications to the core challenges of machining, practical improvement techniques, and real-world applications. Whether you’re an engineer selecting materials for aerospace components, a purchaser sourcing biocompatible medical parts, or a manufacturer optimizing titanium machining processes, this article provides actionable insights to support your decision-making.

Key Properties of Titanium Alloys: Why They Stand Out

Titanium alloys’ widespread adoption in high-precision industries stems from their distinctive physical and mechanical properties, which make them irreplaceable in many critical applications. Understanding these properties is the first step toward successful CNC machining:

- Excellent Strength-to-Weight Ratio: Titanium has a density 30% higher than steel but is nearly 50% lighter. It is 60% heavier than aluminum but twice as strong. This unique balance makes titanium alloys ideal for applications where weight reduction and high strength are paramount, such as aerospace and automotive components.

- Superior Corrosion & Rust Resistance: Titanium forms a stable oxide layer on its surface when exposed to air, which effectively prevents further oxidation and corrosion. This property allows titanium components to perform reliably in harsh environments, including chemical processing, marine settings, and biological systems.

- Biocompatibility: Titanium alloys are non-toxic and have excellent compatibility with human tissues and bones, making them the material of choice for medical implants and surgical instruments.

- Recyclability: Titanium is fully recyclable without losing its key properties, aligning with sustainable manufacturing trends and reducing material waste costs in CNC subtractive processes.

- High Temperature Stability: Certain titanium alloy grades can maintain their strength and creep resistance at temperatures between 400℃ and 600℃, suitable for high-temperature applications like aerospace engine components.

Titanium Alloy Classifications & Common Grades

There are over 100 types of titanium alloys, with 40-50 widely used in industry and more than a dozen being the most common. Based on their microstructure, titanium alloys are classified into three main categories, each with distinct properties and machining characteristics:

1. Alpha (α) Titanium Alloys

Alpha alloys are single-phase alloys composed of alpha solid solution. They maintain a stable alpha-phase structure at both room temperature and higher practical application temperatures, offering better wear resistance and oxidation resistance than pure titanium. They can retain strength and creep resistance at 500℃ to 600℃ but cannot be further strengthened by heat treatment and have relatively low room-temperature strength. Among all titanium alloy categories, alpha alloys have the best machinability.

2. Beta (β) Titanium Alloys

Beta alloys are single-phase alloys composed of beta solid solution. They exhibit high strength without heat treatment, and their strength can be further improved through quenching and aging—room-temperature strength can reach 1372~1666 MPa. However, they have poor thermal stability and are not suitable for high-temperature environments. Beta alloys have the worst machinability among the three categories.

3. Alpha-Beta (α+β) Titanium Alloys

Alpha-beta alloys are dual-phase alloys with excellent comprehensive properties, including good structural stability, toughness, ductility, and high-temperature deformation performance. They can be well hot-pressed and strengthened through quenching and aging—their strength after heat treatment is about 50%~100% higher than that in the annealed state. They have high high-temperature strength and can work continuously at 400℃~500℃, with thermal stability second only to alpha alloys. Their machinability is between alpha and beta alloys.

Common Industrial Grades: The most internationally recognized and widely used titanium alloys are Ti-6Al-4V and Ti-5Al-2.5Sn. Other common grades include Ti-2Al-1.5Mn, Ti-3Al-2.5V, Ti-6Al-2Sn-4Zr-2Mo, Ti-10V-2Fe-3Al, Ti-0.20Pd, and Ti-0.3Mo-0.8N. Among these, Ti-6Al-4V (an α+β alloy) is the workhorse grade, widely used in aerospace, medical, and automotive applications due to its excellent balance of strength and ductility.

Why Is Titanium Alloy Machining So Challenging?

Although the cutting force required for titanium alloy machining is only slightly higher than that for steel of the same hardness, the physical phenomena during titanium machining are far more complex, making it one of the most difficult-to-machine metals. The root cause of these challenges is high temperature generated during the cutting process:

1. Extremely Low Thermal Conductivity

Most titanium alloys have very low thermal conductivity—only 1/7 that of steel and 1/16 that of aluminum. As a result, the heat generated during cutting cannot be quickly transferred to the workpiece or carried away by chips, but instead accumulates in the cutting zone. Temperatures can reach as high as 1000℃, leading to rapid wear, cracking, and built-up edge (BUE) on the tool’s cutting edge. This accelerated tool wear generates even more heat, creating a vicious cycle that further shortens tool life.

2. Surface Integrity Damage & Work Hardening

The high temperature generated during cutting also damages the surface integrity of titanium alloy parts, reducing geometric accuracy and causing work hardening. Work hardening significantly lowers the fatigue strength of the parts, which is critical for high-performance applications like aerospace components.

3. Elastic Deformation & Vibration

Titanium’s elasticity is beneficial for part performance but becomes a major issue during cutting. Cutting pressure causes the "elastic" workpiece to move away from the tool and rebound, resulting in friction between the tool and workpiece that exceeds the cutting force. This friction generates additional heat, exacerbating the problem of poor thermal conductivity and causing vibration (chatter) that impairs surface finish and dimensional accuracy.

Key Techniques to Improve CNC Titanium Alloy Machining

Based on an understanding of titanium machining mechanisms and practical experience, the following technical tips are critical to improving the success rate of CNC titanium alloy machining:

1. Increase Coolant Application

Titanium acts as a thermal insulator, so heat tends to concentrate near the tool. A straightforward heat dissipation method is to use an ample supply of coolant. The working area and tool should be flooded with 10% concentration coolant at high pressure to keep the contact area cool and flush away all hot chips.

2. Use High-Pressure Coolant

For turning operations, the position and pressure of the coolant are crucial. Proper application of high-pressure coolant enables higher surface speeds and metal removal rates. A potential drawback is the redeposition of base material on the part surface, which can be overcome by optimizing cutting strategies and reducing coolant pressure during final finishing.

3. Maintain Constant Feed Rate

Titanium alloys are prone to work hardening—cutting the material makes it harder, which exacerbates tool wear. A constant feed rate ensures that the amount of work-hardened material generated is minimized.

4. Increase Feed Rate (When Possible)

If the machine allows, increasing the feed rate means the tool spends less time in a specific area, leaving less time for heat accumulation and work hardening that can damage the tool’s cutting edge.

5. Select the Right Cutting Tools

PVD-coated carbide inserts are the most suitable tools for cutting titanium alloys. Advanced tool coatings such as TiAlN (titanium aluminum nitride) are also highly recommended. Since titanium is an elastic material, sharp tools are critical—dull tools will scrape the surface and cause machining chatter.

6. Optimize Chip Control

Titanium machining produces long chips that can damage the tool and leave marks on the workpiece surface. Additionally, long, thin chips are not conducive to heat dissipation. Therefore, the ideal tools and toolpaths for titanium machining should produce shorter, thicker chips.

7. Choose Appropriate Toolpaths

Selecting the right toolpath is just as important as choosing the right tool for titanium machining. It is essential to ensure that the toolpath maintains constant contact with the workpiece. When machining grooves, using a trochoidal toolpath can shorten the contact time between the groove and the material, helping to reduce heat accumulation. The process of the tool entering and exiting the workpiece should be smooth to reduce impact and sudden movements, avoiding severe tool damage.

8. Use a Rigid Machine Tool

A robust and durable machine tool is critical for successful titanium alloy machining. An ideal titanium milling machine must have high rigidity, and the spindle must be capable of operating at low speeds and high torque. This helps absorb vibration and reduce chatter commonly encountered during cutting.

Advantages, Disadvantages & Applications of Titanium Alloys

Key Advantages

- Superior Strength-to-Weight Ratio: Enables weight reduction while maintaining high strength, critical for improving fuel efficiency and performance in aerospace and automotive applications.

- Exceptional Corrosion Resistance: Performs reliably in harsh environments such as marine, chemical, and biological settings.

- Excellent Biocompatibility: Non-toxic and compatible with human tissues, making it ideal for medical implants and surgical tools.

- High Temperature Stability: Suitable for high-temperature applications like aerospace engine components.

Main Disadvantages

- High Cost: Titanium does not exist naturally in its pure form and requires complex, energy-intensive processes to extract. This makes both the initial smelting and subsequent machining of titanium alloys much more expensive than other metals.

- Difficult Machining: As detailed earlier, titanium’s low thermal conductivity, elasticity, and work hardening characteristics make machining challenging and require specialized processes and tools.

Key Applications

- Aerospace Industry: The most widely used field for titanium alloys, including engine components, airframe structures, wings, and spars. Ti-6Al-4V is commonly used for its excellent high-temperature strength and corrosion resistance.

- Biomedical Industry: Used for orthopedic implants (e.g., hip and knee replacements), dental implants, and surgical instruments due to its biocompatibility and corrosion resistance in biological environments.

- Automotive Industry: Applied in engine systems (e.g., valve springs) to reduce inertial mass, increase engine speed and output power, and reduce vibration and noise. It also improves fuel efficiency and overall vehicle performance.

- Marine & Chemical Industries: Used for components exposed to saltwater and corrosive chemicals, such as marine fittings, heat exchangers, and chemical processing equipment.

Choose the Right CNC Titanium Alloy Machining Partner

Machining titanium alloys requires specialized expertise in material selection, tooling, and process optimization to overcome its inherent challenges and ensure consistent precision and quality. Partnering with a professional CNC machining service provider with experience in titanium alloy processing is crucial for meeting the strict requirements of high-end applications like aerospace and medical devices.

At SANS, we specialize in CNC titanium alloy machining, with extensive experience processing all common titanium grades (including Ti-6Al-4V, Ti-5Al-2.5Sn) for aerospace, medical, and automotive clients. Our state-of-the-art multi-axis CNC machines, strict quality control system (ISO 9001/AS9100/ISO 13485 certified), and team of skilled engineers ensure precise, efficient, and cost-effective production of titanium alloy parts.

Upload your titanium alloy part’s 2D/3D drawings today, and our engineers will provide a free process evaluation, optimized machining solution, and accurate quotation within 24 hours. Let’s bring your high-precision titanium component ideas to life!

Related Posts

Complete Guide to CNC Stainless Steel Machining: Properties, Grades, Tips & Applications

Stainless steel, a versatile and durable alloy renowned for its corrosion resistance and mechanical strength, has become an indisp...

Complete Guide to CNC Copper Machining: Properties, Alloys, Tips & Applications

Copper, a time-honored industrial metal with exceptional natural properties, has long been a cornerstone in precision manufacturin...

Everything About CNC Aluminum Machining & Aluminum Machined Parts

Aluminum is a relatively new industrial metal with a commercial production history of over 100 years. It is soft, durable, lightwe...

Complete Guide to CNC Plastic Machining: Materials, Tips, Applications & Advantages

Plastics have become indispensable materials in modern manufacturing, valued for their lightweight properties, cost-effectiveness,...