Blog

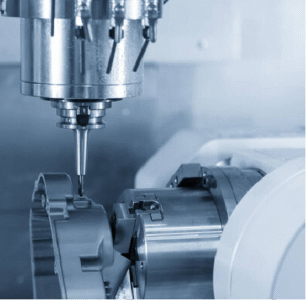

Global Precision Machining Part Manufacturer:Powering Your High-Precision Manufacturing Solutions

As a professional precision machining part manufacturer, we are dedicated to providing high-quality, custom mechanical machining parts for global high-precision manufacturing solutions. With advanced production capabilities, strict quality control systems, and global supply chain support, we serve clients across aerospace, medical devices, automotive electronics, and precision instrumentation industries, becoming a reliable partner for enterprises pursuing excellence in high-precision manufacturing.

Our Core Strengths: Precision, Reliability, and Global Reach

- Advanced Precision Machining Capabilities: Equipped with five-axis linkage machining centers, high-speed precision turning-milling composite machines, and micro-nano machining equipment, we achieve micron-level (±0.001mm) machining accuracy. Our processes cover milling, turning, drilling, grinding, and post-processing, fully meeting the strict requirements of high-precision parts.

- Strict Quality Assurance System: Compliant with ISO 9001, AS9100 (aerospace), and ISO 13485 (medical) standards, we implement full-process quality monitoring—from raw material inspection to online measurement and final product testing—ensuring batch consistency and product reliability.

- Global-Oriented Service & Supply Chain: With rich experience in international trade, we provide one-stop services including custom process design, prototype development, mass production, and global logistics. Our flexible production lines adapt to small-batch, multi-variety orders, meeting diverse needs of global clients.

- Wide Material Adaptability: Proficiency in processing difficult-to-machine materials such as titanium alloy, high-temperature alloy, PEEK, and stainless steel 316L, suitable for high-demand scenarios in various high-precision industries.

Tailored Solutions for Key Global Industries

We focus on matching the core needs of global precision manufacturing, providing targeted machining part solutions for key industries:

Aerospace Industry

Supply high-precision structural parts, engine components, and avionics parts, adhering to AS9100 standards. Strictly control thermal deformation and material performance to ensure parts meet the high reliability requirements of aerospace applications.

Medical Device Industry

Customize biocompatible precision parts (artificial joints, endoscope components) using medical-grade materials. Produce in Class 1000 cleanrooms, complying with ISO 13485 standards to ensure product safety and compatibility.

Automotive Electronics Industry

Mass-produce high-precision sensor cores, automotive connectors, and transmission components, meeting IATF 16949 standards. Ensure batch consistency (error ≤±0.003mm) and high production efficiency to adapt to the fast-paced automotive industry.

Why Choose Us as Your Global Precision Machining Partner?

In the global high-precision manufacturing landscape, we stand out with "precision manufacturing + global service" dual advantages: we not only deliver high-quality, high-accuracy machining parts but also provide efficient communication, fast prototype iteration, and stable logistics support. Whether you are a startup pursuing technological breakthroughs or a well-known enterprise expanding global markets, we can tailor cost-effective, reliable machining solutions to power your core business development.

Contact us today to discuss your precision machining part needs—let’s work together to drive the success of your high-precision manufacturing solutions.

Related Posts

Applications of Non-Standard Parts in the Real World: 5 Practical Uses You’ll Actually See

Non-standard parts are components specially manufactured by various industries to meet unique design and performance requirements....

Standard Parts and Non-Standard Parts

Standard parts and non-standard parts are widely used terminology in the engineering and manufacturing sector.Standard parts refer...

CustomNon-Standard Precision Turned Components | Global Industry-Oriented OEM/ODM Solutions

As a seasoned manufacturer specializing in custom non-standard precision turned components, we deeply cultivate the global market ...

Low-Volume Production Benefits Startups

Low-volume production is quietly emerging as a practical shortcut for startups to turn ideas into tangible products without deplet...

Precision Cleaning: The Critical Role of Ultrasonics in CNC Machined Parts

Precision is the core of CNC machining. However, after milling, turning, or drilling, machined parts typically contain residues—cu...

OEM, ODM, and JDM in Modern Manufacturing

In today's global manufacturing landscape, the relationships between designers, technical developers, and production partners are ...

Development Trends and Innovations of Precision Machining Tools

In the unremitting pursuit of higher precision, superior surface finish, and more efficient machining of increasingly complex mate...

Datum in Geometric Dimensioning and Tolerancing

Geometric Dimensioning and Tolerancing (GD&T) is a crucial tool in the engineering field. It ensures that the assembly and fun...

CNC Precision Machining for Automotive Industry: Driving Safety, Efficiency & Electrification

The automotive industry is undergoing a profound transformation, with a dual focus on enhancing driving safety, improving fuel eff...

CNC Precision Machining for Robotics Manufacturing: Powering High-Accuracy Motion & Reliability

The robotics industry is evolving at a rapid pace, with demands for greater precision, flexibility, and durability across industri...

CNC Precision Machining for Energy Equipment Industry: Powering Reliable & Efficient Energy Solutions

The global energy transition, coupled with the demand for stable, efficient energy supply, has raised unprecedented standards for ...

CNC Machining in the Electronics & Telecommunications Industry: Precision for Connected Technologies

The electronics & telecommunications industry is driven by relentless innovation toward miniaturization, high performance, and...